Discover the Dangers of Consuming Foreign Objects in Your Food

By:Admin

Introduction:

In a recent development, Company X, a prominent player in the food processing industry, has announced a nationwide product recall following the discovery of foreign body contaminants in some of their processed food products. The presence of these foreign bodies, identified as spuds, poses potential health hazards and has necessitated an immediate response from Company X to ensure the safety of consumers. This article will delve into the details of the incident, its potential implications, and the actions undertaken by Company X to address the issue.

Body:

1. Discovery of Foreign Body Spuds:

Earlier this week, customers of Company X's processed food products reported instances of finding foreign bodies resembling small potato pieces, or "spuds," in their purchased items. The discovery set off alarm bells as such contaminants can present choking hazards or other adverse health effects if consumed.

2. Identification of Contaminated Products:

Company X conducted thorough investigations to determine the extent of the issue and identify the specific products affected. Preliminary findings indicate that several batches of processed foods, including various snacks, ready-to-eat meals, and frozen products, contained foreign body spuds. The recall applies to a wide range of brands and flavors, encompassing both national and store-brand offerings.

3. Potential Health Risks:

Consuming food contaminated with foreign bodies can lead to multiple health risks. While chewing on or accidentally swallowing the spuds could pose choking hazards, there are also concerns about damage to the digestive tract or other internal injuries. Additionally, the presence of foreign body contaminants raises concerns regarding overall hygiene and quality control standards at Company X's facilities.

4. Company X's Response and Product Recall:

Demonstrating a commitment to consumer safety, Company X acted swiftly to address the situation. The company launched a product recall, urging consumers to immediately cease consumption and return the identified products for a full refund. The recall initiative extends to all affected products sold within a specified timeframe, regardless of location.

5. Investigation into the Source:

Company X has initiated a rigorous investigation to determine the origin and cause of the foreign body spuds' presence in their processed food products. The investigation will assess various stages of the production line, including supply chain processes, manufacturing, and quality checks. Company X has assured customers that appropriate action will be taken against any parties found responsible for the contamination.

6. Communication and Consumer Support:

In addition to the product recall, Company X has established a dedicated helpline, website, and social media channels to address consumer queries and provide further assistance. The company's communication efforts aim to keep customers informed about the recall process, safety measures, and ongoing investigation updates.

7. Long-Term Measures:

Company X recognizes that this incident calls for a comprehensive review of its quality control protocols and supplier management systems. The company pledges to implement enhanced measures to prevent similar incidents in the future. This commitment includes reinforcing its food safety procedures, conducting more rigorous inspections, and closely collaborating with suppliers on quality control standards.

8. Maintaining Consumer Trust:

The discovery of foreign body spuds in Company X's products poses a significant challenge to the company's reputation and consumer trust. The effectiveness of their recall effort, transparency throughout the investigation, and swift actions to rectify the situation will be essential in safeguarding their long-term brand image.

Conclusion:

The incident involving foreign body spuds found in Company X's processed food products highlights the critical importance of maintaining stringent quality control measures within the food processing industry. As the investigation progresses, it is crucial for Company X to demonstrate its commitment to consumer safety, regain consumer trust, and reinforce its dedication to providing high-quality, hygienic products. Additionally, the incident serves as a reminder for consumers to remain vigilant while choosing and consuming processed foods, underscoring the significance of awareness and engagement to ensure their own well-being.

Company News & Blog

March Sees China's Manufacturing Weaken to Four-Month Low

In March 2012, China experienced a weakening in manufacturing, with an initial reading of a key index hitting a four-month low. This was due to the slowing demand in exports as Europe continues to struggle with its debt crisis.China is known as the world's manufacturing hub, with numerous factories producing a wide range of goods and products. The country's manufacturing sector plays an important role in its economy, providing employment opportunities for millions of people and contributing significantly to the country's GDP.However, China's manufacturing industry is starting to experience a slowdown, with several challenges threatening its growth and development.One of the key challenges faced by China's manufacturing industry is the high cost of labor. The cost of labor in China has been increasing over the years, making it more expensive for factories to produce goods. Furthermore, rising labor costs have resulted in many factories relocating to other countries where labor costs are lower.Another challenge faced by China's manufacturing industry is the increased competition from other countries. Many emerging economies are beginning to invest heavily in their manufacturing industries, offering cheaper labor and better incentives for investments. Countries such as India, Vietnam, and Bangladesh are becoming attractive destinations for foreign investors looking to set up factories.China's manufacturing industry is also threatened by environmental concerns. The country's air and water pollution are significant problems, with many factories contributing to the issue. The Chinese government has introduced several measures to tackle the pollution problem, including tougher regulations and fines for non-compliance. However, these measures are likely to increase the cost of manufacturing and may lead to some investors looking for new locations to set up factories.Overall, the weakening of China's manufacturing industry in March 2012 is a reminder that the industry is not immune to external factors such as economic slowdowns and political uncertainty. To remain competitive, China needs to continue to invest in its manufacturing industry, reduce labor costs, and tackle environmental concerns. The country also needs to explore new markets and niches to remain relevant in the global manufacturing industry.Keywords: China manufacturing, China Manufacture Factory, labor costs, environmental concerns, competition, economic slowdown.

Towel Clamps: The Essential Tool Every Anesthetist Needs

Towel Clamps: The Essential Tool for Medical ProfessionalsTowel clamps are one of the most commonly used instruments in the medical field. They are essential in ensuring that sterile surgical procedures are carried out properly. In this blog post, we will explore what towel clamps are, their functions, and the different types available in the market.What are Towel Clamps?Towel clamps, also known as surgical clips, are specialized clamps used to secure surgical drapes or towels in a sterile field. They ensure that surgical drapes are positioned correctly and securely on the patient, preventing them from slipping or moving during the procedure. Towel clamps are also used to hold sterilization packaging together during the sterilization process.Functions of Towel ClampsTowel clamps are used to prevent contamination and maintain a sterile surgical field. By ensuring that sterile drapes are securely held in place, they minimize the risk of bacterial transmission and prevent surgical site infections. Additionally, towel clamps come in handy in scenarios where the surgical team needs to move and readjust the surgical drapes.Different Types of Towel ClampsThere are various types of towel clamps available in the market. Here are some of the most common ones:1. Backhaus towel clamp - These are the most commonly used towel clamps in surgical procedures. They are designed to grasp and hold the edges of surgical drapes to maintain a sterile field.2. Roeder towel clamp - These clamps are similar to Backhaus towel clamps but have a ratcheted mechanism for easier tightening and loosening.3. Jones towel clamp - Jones towel clamps have jaws that are lined with silicone, ensuring that surgical drapes are held securely in place without damaging them.4. Kelly towel clamp - These clamps are relatively larger than Backhaus towel clamps and are mainly used to secure heavier surgical drapes.5. Lorna towel clamp - These clamps have long and curved jaws, making them ideal for securing surgical drapes in hard-to-reach areas.The Importance of Quality Towel ClampsAs towel clamps are essential to maintaining a sterile surgical field, it is crucial to use high-quality clamps. Cheap and poorly made clamps can lead to surgical site infections, which can be detrimental to the patient's health and well-being.It is also essential to ensure that towel clamps are correctly cleaned and sterilized before use. Failure to do so could result in the transfer of harmful bacteria to the patient, which could lead to infection.ConclusionTowel clamps are an essential tool in the medical field. They ensure that sterile surgical procedures are carried out correctly, minimizing the risk of infection. When choosing towel clamps, it is crucial to pick high-quality clamps that are correctly cleaned and sterilized before use. By doing so, medical professionals can ensure that they are providing their patients with the best possible care.

Comprehensive Guide to Corneal Transplants: Differentiating Dsek, Dsaek, and Dmek procedures

Title: Groundbreaking Corneal Transplants Revolutionize Vision RestorationIntroduction:Corneal diseases are a significant cause of vision impairment and blindness worldwide. In an effort to combat this prevalent issue, medical professionals have been exploring innovative surgical techniques to restore sight. Among the most promising advancements are Descemet Stripping Endothelial Keratoplasty (DSEK), Descemet Membrane Endothelial Keratoplasty (DMEK), and Descemet Stripping Automated Endothelial Keratoplasty (DSAEK). These cutting-edge procedures have revolutionized corneal transplants by enhancing success rates and minimizing complications. This article will delve into the world of corneal transplantation, highlighting these phenomenal techniques and their potential to transform the lives of countless individuals.I. The Advancements in Corneal Transplantation Techniques:Corneal transplantation procedures have come a long way from traditional full-thickness transplants. The emergence of DSEK, DMEK, and DSAEK has significantly improved patient outcomes, promoting faster visual recovery and lesser rejection rates. While the three techniques share similarities, they differ in certain aspects, making each suitable for individual cases.A. DSEK: Descemet Stripping Endothelial Keratoplasty (DSEK) involves replacing only the damaged endothelial layer of the cornea. A small incision is made, and a thin layer of diseased endothelial cells is gently peeled off, while a similar-sized donor tissue is inserted. This technique has introduced quicker visual recovery, decreased astigmatism, and reduced suture-related complications compared to traditional transplants.B. DMEK: Descemet Membrane Endothelial Keratoplasty (DMEK) represents a further refinement of DSEK. In this technique, only the Descemet membrane and endothelium are replaced, excluding any stromal tissue. This approach further reduces graft rejection and enhances visual outcomes, resulting in a more natural vision post-surgery.C. DSAEK: Descemet Stripping Automated Endothelial Keratoplasty (DSAEK) is a modification of DSEK, integrating automated tissue preparation technology. This technique streamlines the procedure and ensures more consistent, thinner grafts for transplantation. DSAEK is particularly beneficial when treating patients with complex corneal diseases such as Fuchs' endothelial dystrophy.II. Contributions of [Company Name]:A. Pioneering Research and Development: [Company Name] has played a pivotal role in pushing the boundaries of corneal transplantation techniques. By tirelessly working towards improving surgical procedures and optimizing patient outcomes, the company has transformed the landscape of ophthalmology.B. Collaborative Approach: The company has actively collaborated with renowned medical professionals and institutions to refine and enhance corneal transplantation techniques. This synergy between experts has expedited advancements in the field, ensuring that patients can access the best possible care.C. State-of-the-Art Equipment and Technology: [Company Name] has consistently invested in cutting-edge equipment and technology to facilitate corneal transplantation procedures. The integration of automated tissue preparation technology, as seen in DSAEK, exemplifies the company's commitment to innovation and improving surgical precision.III. Transforming Lives: The Impact of Advanced TechniquesA. Enhanced Visual Outcomes: DSEK, DMEK, and DSAEK have revolutionized corneal transplantation, providing patients with improved visual outcomes. The techniques offer quicker recovery, reduced astigmatism, and a more natural vision, allowing individuals to regain their independence and enjoy an improved quality of life.B. Reduced Complications: The advanced techniques have significantly reduced complications associated with traditional corneal transplantation. The intricacies of DSEK, DMEK, and DSAEK minimize risk factors such as graft rejection, suture-related issues, and immune responses, ensuring a smooth recovery process for patients.C. Broadening Access to Treatment: The innovative techniques pioneered by [Company Name] have made corneal transplantation more accessible to individuals with complex corneal diseases. By enhancing success rates and minimizing complications, these procedures have extended the benefits of transplantation to a larger population, improving their chances of regaining sight.Conclusion:The advent of DSEK, DMEK, and DSAEK has undoubtedly revolutionized corneal transplantation, offering hope to millions affected by corneal diseases. With their remarkable advancements in visual outcomes, reduced complications, and accessibility to treatment, these techniques have propelled the field forward, empowering countless individuals to reclaim their vision and lead fulfilling lives. Moving forward, continued research and collaborative efforts will allow for further refinement and innovation in corneal transplantation, ultimately benefiting even more patients in need.

High Quality Needle Holders Made of German Stainless Steel Tungsten Carbide

article.Marina Medical Instruments Delivers the Best Needle Holders in the Medical IndustryMarina Medical Instruments, a world-renowned company in the medical supply and distribution industry, continues to deliver high-quality needle holders that are indispensable to medical practitioners everywhere. Its extensive collection of needle holders made of German stainless steel tungsten carbide (TC) inserts precisely and securely grip the needle, making them a cut above the rest.Needle holders are a vital instrument in the medical field, used to hold needles during surgical procedures. Precision in using this instrument is paramount, and this is where Marina Medical Instruments stands out from the rest. With decades of experience in manufacturing high-quality medical instruments, Marina Medical Instruments has become synonymous with reliability and quality.All of the needle holders carried by Marina Medical Instruments are built with German tungsten carbide inserts. This type of tungsten carbide is one of the strongest materials used in the medical industry. It is also incredibly resistant to wear, which means that Marina Medical Instruments needle holders can maintain their functionality in the long term.The TC inserts in Marina Medical Instruments needle holders not only make them durable, but they also play a critical role in ensuring precision in their grip. Marina Medical Instruments needle holders come with smooth jaws that provide a firm grip while minimizing the risk of breaking the needle. The needle is secure, allowing medical professionals to focus on the surgical procedure and not have to worry about the needle slipping out of the grasp of the needle holder.Moreover, Marina Medical Instruments offers a wide variety of needle holders to cater to the diverse needs of its clients. No matter the length or curvature of the needle, their needle holders can precisely grip and securely hold the needle. Some of the most popular needle holders include straight needle holders, curved needle holders, and micro needle holders.The Marina Medical Instruments needle holders are also ergonomic in design, providing medical professionals with comfortable and secure handling. Marina Medical Instruments offers both locking and non-locking options, providing medical practitioners with different options to ensure that they can have the best and safest surgical practice.In addition, Marina Medical Instruments needle holders are easy to clean and maintain. They can be disassembled to facilitate cleaning, which adds to their longevity. The German stainless steel used in its needle holders ensures that they are resistant to rust and so are safe to use.Marina Medical Instruments takes pride in delivering quality and durable medical instruments that meet the highest standards in the industry. The medical equipment company provides medical instruments to medical professionals worldwide, from individual practitioners to top-rated hospitals. Marina Medical Instruments delivers unmatched quality and exceptional customer service that has helped to bolster its reputation as one of the premier medical supply companies in the world.Overall, Marina Medical Instruments Needle Holders are a top of the line product that promises precision, durability, and convenience for medical practitioners. Operating with trust, care, and reliability, Marina Medical Instruments delivers are committed to manufacturing high-quality products that optimize performance and guarantee a high level of patient care.In conclusion, investing in Marina Medical Instruments needle holders assures medical professionals' effectiveness and reliability, which is essential in the medical industry. By choosing Marina Medical Instruments, they can be sure to receive the best needle holders and experience the highest level of customer service in the industry.

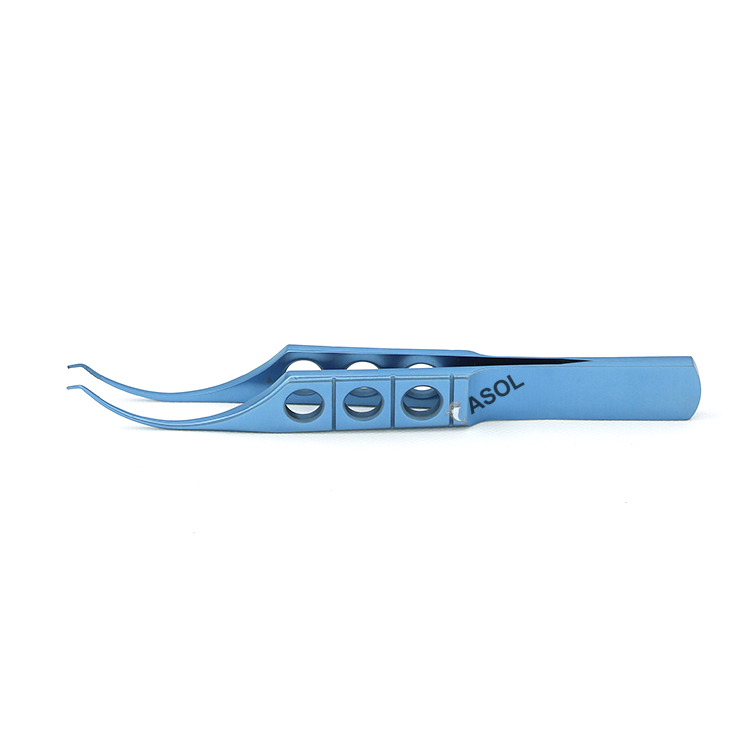

Top 5 Essential Tools Required for Cataract Surgery

[Headline]Revolutionary Advances in Cataract Surgery: Cutting-edge Instruments Enable Enhanced Vision Restoration[Introduction]Advancements in medical technology continue to revolutionize the field of ophthalmology, particularly in the domain of cataract surgery. Leading the way is a pioneering company that has recently introduced state-of-the-art instruments, promising enhanced vision restoration for patients suffering from cataracts. These cutting-edge devices represent a significant leap forward in surgical precision, efficacy, and patient outcomes. This article aims to provide an overview of these groundbreaking instruments, exploring their unique features and potential impact on cataract treatment.[Body]A Superior Approach to Cataract SurgeryCataract surgery has long been recognized as a safe and effective procedure for restoring vision impaired by cataracts, a condition characterized by the clouding of the eye's natural lens. Conventionally, cataract removal involved making a small incision and using ultrasound energy to break up and remove the cloudy lens, followed by implanting a clear intraocular lens (IOL) to restore vision. However, recent advancements in cataract surgical instruments have revolutionized the approach to this prevalent eye condition.Enter the New Generation of Cataract InstrumentsA company at the forefront of these breakthroughs has recently unveiled its cutting-edge instruments, transforming the landscape of cataract surgery. These instruments incorporate a combination of innovative technologies and design elements to provide surgeons with unprecedented precision and control during the procedure.Advanced Optical Guidance SystemOne key component of these instruments is the advanced optical guidance system. By integrating high-resolution imaging capabilities with sophisticated software algorithms, surgeons can now visualize the eye's internal structures with exceptional detail, aiding in more precise incisions and lens manipulation. This revolutionary feature allows surgeons to achieve optimal outcomes tailored to individual patients, facilitating customized treatment plans.Automated Capsulotomy TechnologyAnother remarkable inclusion in these instruments is the automated capsulotomy technology. This feature enables the creation of a perfectly circular, well-centered opening in the front portion of the eye's natural lens capsule, necessary for seamless intraocular lens placement. The automated precision of this technology significantly reduces the potential for human error and ensures optimal positioning of the IOL, ultimately enhancing the patient's visual outcome.Ergonomic Design and Ease of UseRecognizing the importance of surgeon comfort and control, the company has meticulously designed these instruments with ergonomics in mind. The lightweight, easy-to-handle tools allow surgeons to perform complex maneuvers with precision and stability, minimizing fatigue during lengthy surgical sessions. This user-friendly interface enhances surgical accuracy and promotes favorable patient outcomes.Unlocking New Possibilities in Cataract SurgeryThe introduction of these cutting-edge cataract instruments opens up a world of possibilities for patients and surgeons alike. The enhanced precision, accuracy, and user-friendliness of these devices enable surgeons to tackle even the most complex cases with increased confidence.Improved Patient OutcomesThese advancements directly translate into improved patient outcomes. With instruments that boast such remarkable capabilities, surgeons are better equipped to address unique anatomical challenges, resulting in improved visual acuity and quality of life for patients. Furthermore, the reduced risk of complications associated with the automated features minimizes the potential for post-operative complications and amplifies the success rates of cataract surgeries.ConclusionThe advent of these innovative cataract instruments represents a significant turning point in the field of ophthalmology. Surgeons now have access to cutting-edge tools that empower them to deliver unparalleled surgical precision and restore vision with exceptional outcomes. As these groundbreaking instruments continue to evolve, we can only imagine the limitless potential they hold for future advancements in cataract surgery.

Supplier of High-Quality Capsule Polishing Machines in China

: What They Are, How They Work, and Why They're ImportantCapsule polishers play a crucial role in the manufacturing process of pharmaceuticals and dietary supplements. As the name suggests, these machines are used to polish capsules to ensure that they are free from dust, dirt, and other contaminants. In this blog post, we'll take a closer look at what capsule polishers are, how they work, and why they're so important.What are Capsule Polishers?Capsule polishers are machines that are used to clean and polish capsules after they have been filled with medication or other substances. This is an important step in the manufacturing process, as even the smallest particles can cause problems in the final product. Capsule polishers are specifically designed to remove dust, dirt, and other contaminants from the surface of the capsules, ensuring that they are completely clean and ready for packaging.How do Capsule Polishers Work?Capsule polishers work by using a variety of techniques to clean and polish the capsules. One common method is air scrubbing, which involves blowing air over the surface of the capsules to remove any dust or dirt. Another technique is light abrasion, which involves using a soft brush or pad to gently scrub the capsules. Some capsule polishers also use vacuums to remove any loose particles that are removed during the cleaning process.Why are Capsule Polishers Important?Capsule polishers are important for several reasons. First, they help to ensure that the capsules are free from contaminants that can affect the quality of the medication or supplement. Even small particles can cause problems such as clogging machinery or affecting the stability of the product. By removing these particles, capsule polishers help to ensure that the final product is of the highest quality.Another reason why capsule polishers are important is that they help to increase the efficiency of the manufacturing process. By removing contaminants from the surface of the capsules, they reduce the need for manual inspection and can help to speed up the production process. This not only saves time and money, but also helps to ensure that the final product is delivered to the customer on time.ConclusionCapsule polishers play a critical role in the manufacturing process of pharmaceuticals and dietary supplements. By removing contaminants from the surface of the capsules, they help to ensure that the final product is of the highest quality. They also help to increase the efficiency of the manufacturing process, which saves time and money. Whether you're a manufacturer of pharmaceuticals or dietary supplements, investing in a high-quality capsule polisher is a smart decision that will pay off in the long run.

Durable Sterilization Trays for Medical Instruments: Plastic and Metal Options Available

Plastic and metal sterilization trays are essential tools used in the healthcare industry to prevent the spread of infectious diseases and bacteria. Sterilization trays are designed to hold medical instruments and equipment while they undergo various sterilization processes such as autoclaving, chemical sterilization, and other disinfection processes.One of the most commonly used types of sterilization trays is plastic instrument trays. These trays are lightweight, durable, and easy to clean, making them a popular choice for medical professionals. Millennium Surgical Plastic Instrument Trays, for example, are made of high-quality plastic that is resistant to chemicals and heat. They come in different sizes and configurations to accommodate a wide range of medical instruments.Another type of sterilization tray is metal sterilization trays. These trays are typically made of stainless steel and are designed to withstand high temperatures and harsh chemicals. They are durable, long-lasting, and provide excellent protection against contamination. Metal sterilization trays, such as the Orthopedic Instrument Racks, are ideal for holding heavy and bulky medical instruments.Flash GuardTM and Immediate Use sterilization trays are two other types of sterilization trays that are designed for quick and easy sterilization. Flash GuardTM sterilization trays are designed to be used in emergency situations where time is of the essence. These trays are pre-sterilized and ready to use right out of the package. Immediate Use sterilization trays, on the other hand, are designed for sterilizing small amounts of instruments quickly and efficiently.Micro Instrument Sterilization Trays are specially designed for holding delicate and small medical instruments. These trays are equipped with micro-mesh bottoms that prevent small instruments from falling through and being lost during the sterilization process. Laparoscopic and endoscopic trays are also available for holding delicate laparoscopic and endoscopic instruments.Stringers, racks, and accessories are other important components of sterilization trays. These additions help to organize and secure medical instruments during the sterilization process. They also help to protect instruments from damage during transportation and storage.In conclusion, sterilization trays are important tools used in the healthcare industry to prevent the spread of infectious diseases and bacteria. Plastic and metal sterilization trays are widely used and come in various sizes and configurations to accommodate a wide range of medical instruments. Flash GuardTM and Immediate Use sterilization trays are designed for quick and easy sterilization, while Micro Instrument Sterilization Trays are designed for delicate and small instruments. Stringers, racks, and accessories are also essential components of sterilization trays that help to organize and secure medical instruments during the sterilization process.

Miniature Scissors Used in Surgery Show Promise in Reducing Tissue Damage

Title: Precision and Efficiency Define the New Era of Surgical ScissorsIntroduction:In the rapidly advancing field of medicine, surgical procedures play a pivotal role in saving lives and improving patient outcomes. Among the wide range of instruments used during surgical interventions, small surgical scissors have become indispensable tools due to their precision, versatility, and ability to perform delicate procedures with accuracy. Leading the way in this domain is a pioneering company [Company Name], renowned for their innovative range of small surgical scissors that exceed industry standards. With their unmatched quality and commitment to enhancing surgical outcomes, [Company Name] is revolutionizing the field of surgical instrumentation.I. [Company Name]: Redefining Surgical Instrumentation[Company Name] is a globally recognized manufacturer and provider of cutting-edge medical equipment, aiming to improve patient care through continuous innovation and technological advancements. With a commitment to delivering precision instruments to medical professionals, the company has become a trusted partner in operating rooms worldwide. By seamlessly blending research, design, and engineering expertise, [Company Name] boasts an extensive portfolio of surgical solutions that encompass a wide range of specialties.II. Unveiling the All-New Small Surgical Scissors RangeRecognizing the vital role played by small surgical scissors in the surgical environment, [Company Name] has unveiled a new cutting-edge line of small surgical scissors designed to revolutionize precision and efficiency during critical procedures. These state-of-the-art scissors showcase the following features:a) Enhanced Precision: The small surgical scissors offered by [Company Name] are meticulously designed to provide unparalleled precision during delicate procedures. Their ultra-sharp stainless steel blades ensure smooth and accurate incisions, minimizing tissue trauma and promoting faster healing.b) Ergonomic Design: Understanding the importance of ergonomics in preventing surgeon fatigue and optimizing performance, [Company Name] has integrated innovative ergonomic features into their small surgical scissors. The design offers a comfortable grip, reducing hand strain and improving maneuverability, ultimately enhancing surgical outcomes.c) Versatile Options: [Company Name]'s small surgical scissors come in a plethora of designs, sizes, and specialized variations, catering to the unique requirements of different surgical procedures. The range includes fine-point scissors for meticulous dissections, curved scissors for hard-to-reach areas, and specialized scissors for intricate procedures.III. Advancing Surgical Efficiency and Patient SafetyThe introduction of [Company Name]'s small surgical scissors has ushered in a new era of surgical precision and efficiency. By utilizing these cutting-edge instruments, surgeons can perform intricate procedures with confidence, ensuring minimal tissue damage and reduced operative times. Key benefits offered by the small surgical scissors include:a) Faster Healing: The precise incisions made by [Company Name]'s small surgical scissors minimize tissue trauma, resulting in faster healing times for patients. This leads to reduced post-operative pain, decreased risk of complications, and improved overall patient satisfaction.b) Minimized Blood Loss: With their razor-sharp blades and delicate scissor tips, these instruments afford precise control, minimizing blood loss during surgery. This leads to improved visualization, reduced transfusion requirements, and enhanced patient safety.c) Streamlined Operations: The ergonomic design and versatility of [Company Name]'s small surgical scissors streamline surgical procedures. Surgeons can work more efficiently, reducing operative times and enhancing overall OR productivity.IV. Commitment to Quality and Innovation[Company Name] has always been at the forefront of innovation in surgical instrument manufacturing. Their small surgical scissors reflect the company's unwavering commitment to quality and technological advancement. Rigorous quality control measures are in place throughout the production process, ensuring that each pair of scissors meets or exceeds industry standards. Furthermore, [Company Name] continuously incorporates feedback from surgeons and healthcare practitioners, leading to the development of new iterations and improvements in their products.Conclusion:As the demand for precision and efficiency in surgical procedures continues to grow, [Company Name]'s small surgical scissors emerge as pioneering instruments, revolutionizing the field. By combining advanced technology, superior design, and a commitment to patient care, [Company Name] provides surgeons with the versatile tools necessary to elevate surgical outcomes. With their unwavering dedication to quality and innovation, [Company Name] is set to shape the future of surgical instrumentation, paving the way for more successful and less invasive surgical interventions.

Temporal Speculum with Solid Blades for Accurate Eye Examinations

A speculum is a medical tool that is used to spread open a patient's body orifice in order to perform a medical examination or procedure. The speculum is commonly used in gynecology, ear, nose and throat (ENT) medicine, and ophthalmology. One of the most commonly used speculums in ophthalmology is the Barraquer speculum. The Barraquer speculum is designed to hold the eyelids open during surgeries such as cataract surgery, glaucoma surgery, and corneal transplant surgery. Today, we will be discussing the Barraquer speculum with solid blades.The Barraquer speculum with solid blades is a temporal speculum that is used to hold the eye open during ophthalmic surgery. This particular speculum is unique because it has solid blades, which are designed to be more durable and longer-lasting than traditional, hollow-bladed speculums. The solid blades are also less prone to bending or breaking during use, which makes them a more reliable option for ophthalmologists and eye surgeons.One of the key benefits of the Barraquer speculum with solid blades is its design. The solid blades are designed to fit securely around the patient's eye without causing any discomfort or pain. The temporal arms of the speculum are also adjustable, which allows the surgeon to customize the fit of the speculum for each individual patient. This feature is particularly useful for patients with small or large eyes, or for patients who have undergone previous eye surgeries.Another benefit of the Barraquer speculum with solid blades is its durability. The solid blades are made from high-quality stainless steel, which makes them resistant to corrosion and wear. This means that the speculum can be used repeatedly without the need for frequent replacement or repair. The durability of the solid blades also makes the speculum a cost-effective option for ophthalmic clinics and hospitals.In addition to its durability and design, the Barraquer speculum with solid blades is also easy to clean and sterilize. The speculum can be disassembled for thorough cleaning, which helps to prevent the spread of infectious disease. The solid blades can also be sterilized using a variety of methods, including chemical sterilization and autoclaving.Overall, the Barraquer speculum with solid blades is a reliable and effective tool for ophthalmic surgery. Its unique design, durability, and ease of use make it a preferred choice for many eye surgeons and ophthalmologists. If you are in the market for a new speculum for your ophthalmic practice, be sure to consider the Barraquer speculum with solid blades. With its solid blades design, you can be confident in the long-lasting and reliable performance it provides.

Discover the Dangers of Consuming Foreign Objects in Your Food

Title: Foreign Body Spuds in Processed Foods Prompt Company X to Initiate Product RecallIntroduction:In a recent development, Company X, a prominent player in the food processing industry, has announced a nationwide product recall following the discovery of foreign body contaminants in some of their processed food products. The presence of these foreign bodies, identified as spuds, poses potential health hazards and has necessitated an immediate response from Company X to ensure the safety of consumers. This article will delve into the details of the incident, its potential implications, and the actions undertaken by Company X to address the issue.Body:1. Discovery of Foreign Body Spuds:Earlier this week, customers of Company X's processed food products reported instances of finding foreign bodies resembling small potato pieces, or "spuds," in their purchased items. The discovery set off alarm bells as such contaminants can present choking hazards or other adverse health effects if consumed.2. Identification of Contaminated Products:Company X conducted thorough investigations to determine the extent of the issue and identify the specific products affected. Preliminary findings indicate that several batches of processed foods, including various snacks, ready-to-eat meals, and frozen products, contained foreign body spuds. The recall applies to a wide range of brands and flavors, encompassing both national and store-brand offerings.3. Potential Health Risks:Consuming food contaminated with foreign bodies can lead to multiple health risks. While chewing on or accidentally swallowing the spuds could pose choking hazards, there are also concerns about damage to the digestive tract or other internal injuries. Additionally, the presence of foreign body contaminants raises concerns regarding overall hygiene and quality control standards at Company X's facilities.4. Company X's Response and Product Recall:Demonstrating a commitment to consumer safety, Company X acted swiftly to address the situation. The company launched a product recall, urging consumers to immediately cease consumption and return the identified products for a full refund. The recall initiative extends to all affected products sold within a specified timeframe, regardless of location.5. Investigation into the Source:Company X has initiated a rigorous investigation to determine the origin and cause of the foreign body spuds' presence in their processed food products. The investigation will assess various stages of the production line, including supply chain processes, manufacturing, and quality checks. Company X has assured customers that appropriate action will be taken against any parties found responsible for the contamination.6. Communication and Consumer Support:In addition to the product recall, Company X has established a dedicated helpline, website, and social media channels to address consumer queries and provide further assistance. The company's communication efforts aim to keep customers informed about the recall process, safety measures, and ongoing investigation updates.7. Long-Term Measures:Company X recognizes that this incident calls for a comprehensive review of its quality control protocols and supplier management systems. The company pledges to implement enhanced measures to prevent similar incidents in the future. This commitment includes reinforcing its food safety procedures, conducting more rigorous inspections, and closely collaborating with suppliers on quality control standards.8. Maintaining Consumer Trust:The discovery of foreign body spuds in Company X's products poses a significant challenge to the company's reputation and consumer trust. The effectiveness of their recall effort, transparency throughout the investigation, and swift actions to rectify the situation will be essential in safeguarding their long-term brand image.Conclusion:The incident involving foreign body spuds found in Company X's processed food products highlights the critical importance of maintaining stringent quality control measures within the food processing industry. As the investigation progresses, it is crucial for Company X to demonstrate its commitment to consumer safety, regain consumer trust, and reinforce its dedication to providing high-quality, hygienic products. Additionally, the incident serves as a reminder for consumers to remain vigilant while choosing and consuming processed foods, underscoring the significance of awareness and engagement to ensure their own well-being.